Self Compacting Concrete

Published on Feb 14, 2016

Abstract

Japan has used self-compacting concrete (SCC) in bridge, building and tunnel construction since the early 1990.s. In the last five years, a number of SCC bridges have been constructed in Europe. In the United States, the application of SCC in highway bridge construction is very limited at this time.

However, the U.S. precast concrete industry is beginning to apply the technology to architectural concrete. SCC has high potential for wider structural applications in highway bridge construction.

The application of concrete without vibration in highway bridge construction is not new. For examples, placement of seal concrete underwater is done by the use of a tremie without vibration, mass concrete has been placed without vibration, and shaft concrete can be successfully placed without vibration. These seal, mass and shaft concretes are generally of lower strength, less than 34.5 MPa and difficult to attain consistent quality. Modern application of selfcompacting concrete (SCC) is focused on high performance . better and more reliable quality, dense and uniform surface texture, improved durability, high strength, and faster construction.

Recognizing the lack of uniformity and complete compaction of concrete by vibration, researchers at the University of Tokyo, Japan, started out in late 1980.s to develop SCC. By the early 1990.s, Japan has developed and used SCC that does not require vibration to achieve full compaction. More and more applications of SCC in construction have been reported in Japan. As of the year 2000, the amount of SCC used for prefabricated products (precast members) and ready-mixed concrete (cast-in-place) in Japan was about 400,000 m3.

DEVELOPING SCC MIXES

SCC mixes must meet three key properties:

1. Ability to flow into and completely fill intricate and complex forms under its own weight.

2. Ability to pass through and bond to congested reinforcement under its own weight.

3. High resistance to aggregate segregation.

The SCC mixes are designed and tested to meet the demands of the projects. For example, the mix for mass concrete is designed for pumping and depositing at a fairly high rate. SCC was used in the construction of the anchorages of the Akashi-Kaikyo Suspension Bridge.

The SCC was mixed at a batch plant at the job site and pumped through a piping system to the location of the anchorages 200 m away. The SCC was dropped from a height of as much as 5 m without aggregate segregation. For mass concrete, the maximum size of coarse aggregates may be as large as 50 mm. The SCC construction reduced the construction time for the anchorages from 2.5 years to 2 years. Similarly, SCC mixes can be designed and placed successfully for concrete members with normal and congested reinforcement. The coarse aggregate size for reinforced concrete generally varies from 10 mm to 20 mm.

EXAMPLES OF SCC MIXES:

When designing an SCC mix, a suitable mix is selected among .Powder- type. by increasing the powder content, .VMA-type. using viscosity modifying admixture and .Combined- type. by increasing powder content and using viscosity agent in consideration of structural conditions, constructional conditions, available material, restrictions in concrete production plant, etc. Examples of SCC mixes are given in the following tables to provide a feel for how SCC mixes differ from normal concrete mixes and from each other based on the specific needs of a project. In comparison to the conventional concrete, all three types work with an increased amount of superplasticizer.

PROPERTIES OF FRESH SCC

The main characteristics of SCC are the properties in the fresh state. SCC mix design is focused on the ability to flow under its own weight without vibration, the ability to flow through heavily congested reinforcement under its own weight, and the ability to obtain homogeneity without segregation of aggregates. Several test methods are available to evaluate these main characteristics of SCC. The tests have not been standardized by national or international organizations.

TEST METHODS FOR FRESH SCC

The Slump Flow Test

1)This is a test method for evaluating the flowability of SCC, where the slump flow of SCC with coarse aggregates having the maximum size of less than 40 mm is measured

2). The basic equipment is the same as for the conventional slump test. However, the concrete placed into the mold is not rodded. When the slump cone has been lifted and the sample has collapsed, the diameter of the spread is measured rather than the vertical distance of the collapse.

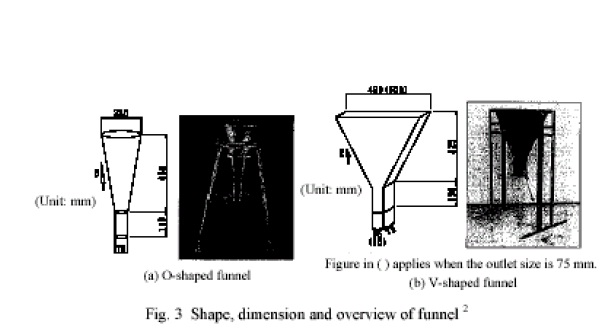

Funnel Test

A test method for evaluating the material segregation resistance of SCC, using a funnel as shown in Fig. 3, where the efflux time of SCC with coarse aggregates having the maximum size of less than 25 mm is measured.

T50 Test A test method for evaluating the material segregation resistance of SCC, where the 500-mm flow reach time is measured in the slump flow test above, that is, the time for the flow to reach 500 mm is measured in the slump flow test. SCC should give T50 = 2 . 5 seconds. U-Type and Box-Type Tests These are methods for testing flowability of SCC through an obstacle with coarse aggregates having the maximum size of less than 25 mm (Fig. 4 and Photo 1). Time and height to be filled in the chamber B and amount of aggregate passed through the obstacle are measured for self-compactability.