E-Nose

Published on Dec 12, 2015

Abstract

In an ever-developing world, where electronic devices are duplicating every other sense of perception, the sense of smell is lagging behind. Yet, recently, there has been an urgent increase in the need for detecting odours, to replace the human job of sensing and quantification.

Some of the most important applications fall in the category where human beings cannot afford to risk smelling the substance. Other important applications are continuous monitoring, medical applications, etc. These applications allow man to perform tasks that were once considered impossible.The fast paced technology has helped develop sophisticated devices that have brought the electronic nose to miniature sizes and advanced capabilities. The trend is such that there will be accurate, qualitative and quantitative measurements of odour in the near future.

Living beings interact with the surrounding environment through particular interfaces called senses, which can be divided in two groups: those detecting physical quantities and those detecting chemical quantities.

Physical interfaces (that deals with acoustic, optic, temperature and mechanic interaction mechanisms) are sufficiently well known and a wealth of successful studies to construct their artificial counterparts has been done in the past years. On the other side the chemical interfaces (bio transducers of chemical species in air: olfaction, and in solution: taste) even if well described in literature, present some aspects of their physiological working principal that are still unclear. It has also to be remarked a psychological difference, in human beings, between the two groups.

Indeed the information from the physical senses can be adequately elaborated, verbally expressed, firmly memorized and fully communicated. On the contrary chemical information, coming from nose and tongue, are surrounded by vagueness and this is reflected in the poor description and memorization capacity in reporting olfactory and tasting experiences. Chemical information is of primary importance for the major part of the animals; for many of them, indeed, chemistry is the unique realm of which they are concerned, while for human beings evolution has enhanced about exclusively the physical interfaces, leaving little care of the chemical interface, if we exclude unconscious acquisition and side behaviours.

For these intrinsic difficulties toward the understanding of the nature of these senses for many years only sporadic research on the possibility of fabricating artificial olfactory systems were performed. Only at the end of the eighties a new and promising approach was introduced. It was based on the assumption that an array of non-selective chemical sensors, matched with a suitable data processing method, could mimic the functions of olfaction.

In the past decade, electronic nose instrumentation has generated much interest internationally for its potential to solve a wide variety of problems in fragrance and cosmetics production, food and beverages manufacturing, chemical engineering, environmental monitoring, and more recently, medical diagnostics and bioprocesses. Several dozen companies are now designing and selling electronic nose units globally for a wide variety of expanding markets. An electronic nose is a machine that is designed to detect and discriminate among complex odours using a sensor array. The sensor array of consists of broadly tuned (non-specific) sensors that are treated with a variety of odour-sensitive biological or chemical materials.

An odour stimulus generates a characteristic fingerprint (or smell-print) from the sensor array. Patterns or fingerprints from known odours are used to construct a database and train a pattern recognition system so that unknown odours can subsequently be classified and identified. Thus, electronic nose instruments are comprised of hardware components to collect and transport odours to the sensor array - as well as electronic circuitry to digitise and stored the sensor responses for signal processing.

Principle of E-nose

Mimicking the nose is a challenging task. The human nose can smell 10,000 different odour molecules mixed in air. Odour in a substance is due to certain volatile organic compounds (VOCs), which easily evaporate and get carried by an air stream. An e-nose can smell and estimate odours quickly though it has little or no resemblance to the human nose.

A human nose has receptors, which serve as binding sites for VOCs. A receptor is just a molecular structure on the surface of the nerve cell to which an odorous molecule with the right shape binds. The receptor and the binding molecule fit exactly as in a key and lock arrangement. These odour-sensing nerve cells line the upper part of the cavity in the human nose.

Once an odour molecule binds to a receptor, a chain reaction follows which ultimately transmits an electrical signal to the brain. A specific odour of coffee or wine is usually caused not by one, but a mixture of hundreds of organic compounds. So, the brain has a mammoth task of processing signals received from the nerve cells originating from the nose, to identify the nature of smell. The exact working of the brain in processing these signals is yet to be fully understood.

An electronic nose can be defined as ‘an instrument which is comprised of an array of electronic chemical sensors with partial specificity and an appropriate pattern recognition system, capable of recognizing simple or complex odours (and other gaseous mixtures). The ability of an electronic nose to rapidly discriminate between slight variations in complex mixtures makes the techniques ideal for on-line process diagnostics and screening across a wide range of application areas. An electronic nose is a machine that is designed to detect and discriminate among complex odours using a sensor array.

The sensor array of consists of broadly tuned (non-specific) sensors that are treated with a variety of odour-sensitive biological or chemical materials. An odour stimulus generates a characteristic fingerprint (or smell-print) from the sensor array. Patterns or fingerprints from known odours are used to construct a database and train a pattern recognition system so that unknown odours can subsequently be classified and identified. Thus, electronic nose instruments are comprised of hardware components to collect and transport odours to the sensor array – as well as electronic circuitry to digitise and stored the sensor responses for signal processing.

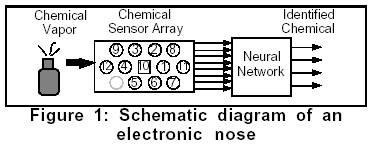

The two main components of an electronic nose are the sensing system and the automated pattern recognition system. The sensing system can be an array of several different sensing elements (e.g., chemical sensors), where each element measures a different property of the sensed chemical, or it can be a single sensing device (e.g., spectrometer) that produces an array of measurements for each chemical, or it can be a combination. Each chemical vapour presented to the sensor array produces a signature or pattern characteristic of the vapour. By presenting many different chemicals to the sensor array, a database of signatures is built up. This database of labelled signatures is used to train the pattern recognition system.

The goal of this training process is to configure the recognition system to produce unique classifications of each chemical so that an automated identification can be implemented. The quantity and complexity of the data collected by sensors array can make conventional chemical analysis of data in an automated fashion difficult. One approach to chemical vapour identification is to build an array of sensors, where each sensor in the array is designed to respond to a specific chemical. With this approach, the number of unique sensors must be at least as great as the number of chemicals being monitored. It is both expensive and difficult to build highly selective chemical sensors. Artificial neural networks (ANNs), which have been used to analyse complex data and to recognize patterns, are showing promising results in chemical vapour recognition.

When an ANN is combined with a sensor array, the number of detectable chemicals is generally greater than the number of sensors. Also, less selective sensors, which are generally less expensive, can be used with this approach. Once the ANN is trained for chemical vapour recognition, operation consists of propagating the sensor data through the network. Since this is simply a series of vector-matrix multiplications, unknown chemicals can be rapidly identified in the field. Electronic noses that incorporate ANNs have been demonstrated in various applications. Some of these applications will be discussed later in the paper. Many ANN configurations and training algorithms have been used to build electronic noses including back propagation-trained, feed-forward networks; fuzzy ART maps; Cohune’s self-organizing maps (SOMs); learning vector quantizers (LVQs); Hamming networks; Boltzmann machines; and Hopfield networks. Figure 1 illustrates the basic schematic of an electronic nose.

2.2. Sensing an Odorant

In a typical e-nose, an air sample is pulled by a vacuum pump through a tube into a small chamber housing the electronic sensor array. The tube may be of plastic or stainless steel. A sample-handling unit exposes the sensors to the odorant, producing a transient response as the VOCs interact with the active material. The sensor response is recorded and delivered to the signal-processing unit. Then a washing gas such as alcohol is applied to the array for a few seconds or a minute, so as to remove the odorant mixture from the active material. Finally, the reference gas is again applied to the array, to prepare it for a new measurement cycle. The odorant is applied for a period equal to the response time of the sensor array. The washing and reference gases are applied for the sensor array to recover and come to a reference point. This duration is termed the recovery time.